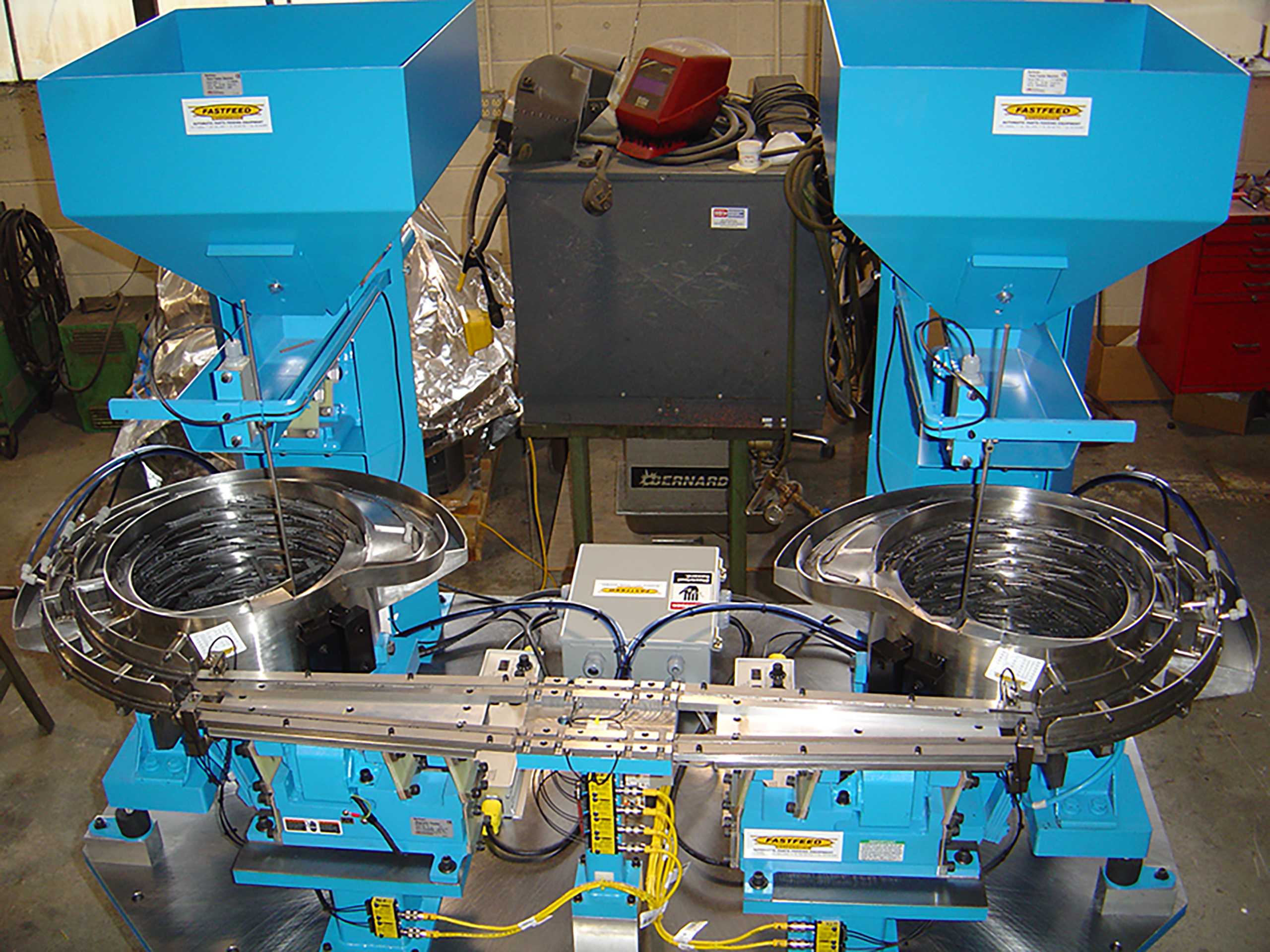

Parts Feeding & Loading Systems

Parts Feeding & Loading Systems are proven to integrate seamlessly with your existing machinery and process, handling parts in a consistent repeatable way.

Custom-Built

We have worked with various small parts feeding applications throughout our history, giving us the knowledge to design and manufacture parts feeding & orientation equipment to optimize your production feed rates cost-effectively. Some parts include fasteners, stamped parts, molded parts, and cold-headed parts.

What Sets Us Apart

Typical competitive designs include a vibratory bowl feeder and track in the market. Fastfeed’s standard design comes fitted with a custom Pick & Place to help place your part correctly oriented into the next stage of your process.

Applications

Promotes faster, more consistent production in applications dealing with manufacturing, feeding, sorting, inspecting, assembling, quality control, or packaging challenges. Typical applications include turnkey solutions for loading into a customer’s fixture, indexing dial, CNC machine, and automatic welder, to name a few.

Fastfeed provides an on-site review to provide a tailored Automated Parts Feeding System to best suit your facility, process, and specific job requirements.

Parts Feeding & Loading System Product Details

Learn about Fastfeed’s Parts Feeding & Loading System and how they can help increase production times and improve process efficiencies.

How Automated Parts Feeding & Loading Systems Work

Automated Parts Feeding & Loading Systems take bulk parts from a hopper or conveyor to a Vibratory Bowl Feeder. This then feeds to a vibratory inline, conveyor, gravity track, or rotate nest, etc. The parts can then be automatically placed or loaded to the next machine or process often using a Pick & Place, Dial Indexer, or Robot.

Take Your System to the Next Level

Easily identify, qualify, and sort your parts by upgrading your system with Fastfeed’s Parts Vision Inspection System. With the use of additional cameras and sensors, you can boost productivity and shorten process times, ensuring your parts are placed accurately and consistently.

Design Capabilities

Fastfeed’s team will work with your team and help conceptualize, design, and build a system that meets your exact technical requirements. We strive to help solve your production challenge and fit within your budget and production goals.

Typical Design Standards Include:

- 3D Solid Model Design

- Heavy Duty Base

- Bulk Supply Storage Hopper

- Vibratory Bowl Feeder

- Accumulation track (vibratory in-line, conveyor, gravity track)

- Escapement device to isolate parts for pick up and/or multiple positions for two-out, three-out, four-out, etc.

- Heavy Duty Pick & Place

Do you use Fastfeed’s products in your facility? You can submit images like these in exchange for free marketing content and Fastfeed swag. Learn more today!

See Our Products in Action!

Interested in learning more about how Fastfeed products can improve your automation process?