Do you have a piece of old automation equipment that no longer fits your needs? Do you have outdated assembly equipment that is collecting dust and taking up valuable production space? Fastfeed has a number of turnkey automation solutions that can help repurpose your existing equipment – whether we made it or not – to increase your company’s manufacturing efficiencies.

Fastfeed’s 3R program can impact your bottom line

Fastfeed offers an affordable and comprehensive 3R program that can REFURBISH, RETOOL, or REBUILD your existing machinery to modify and/or upgrade it to fit the demands of your changing needs. In many cases, you’ll save up to 50% of the cost of buying a new piece of machinery which can have an immediate impact on your bottom line. Furthermore, the Fastfeed team will even retool our competitors’ systems if that makes the most sense for you and your business. Above all, Fastfeed’s 3R program can help your operation save money and increase overall production capacity.

Old equipment, new applications

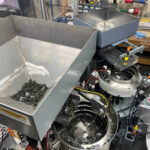

On this project, our customer took an existing piece of equipment previously utilized for testing purposes only and had it significantly refurbished for use on the assembly line. Here’s a look at the unit before we worked our magic:

Although the unit originally featured a single feeder bowl used to orient and test plastic clips in the aerospace industry, the talented team at Fastfeed was able to retool the machine and install a second bowl feeder. The new addition introduced an additional item and functions to their manufacturing process, greatly increasing production capacity and overall efficiencies.

Afterward, the company enjoyed the benefits of having a custom-built, dual-indexing unit that served multiple purposes. Not only did it continue with its ability to perform a critical quality check, but after the work was completed, it could also be utilized on the assembly line with full production capacity.

Here’s a look at the finished project:

Custom solutions waiting to fit your needs

Let the Fastfeed team of #ProcessAutomationPros keep your operation running smoothly and efficiently without unnecessary expense and prolonged downtime. If you have a problem with your production line, Fastfeed has a solution.

Contact our #ProcessAutomationPros today to learn more.

Click here for more information: https://bit.ly/3MdusW1.

#automation #automationsystems #automationsolutions

#automationindustry #refurbish #retool #rebuild

#bowlfeeder #feeder #aerospaceindustry

#aerospaceengineering #metalstamping #weldnut

#weldstud #fastener #fasteners

Recent Comments